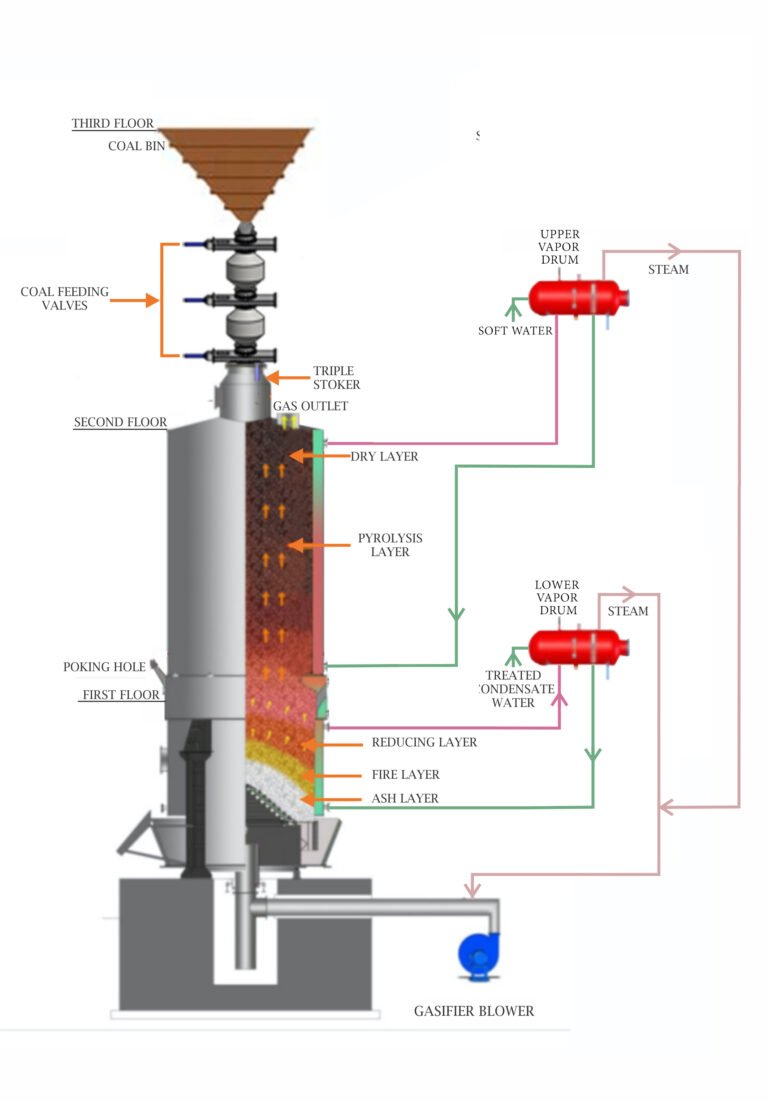

COLD COAL GASIFIER

PYROLYSIS FIXED BED

Gasification is the process of extracting maximum amount of energy from combustible materials like coal, biomass and other carbonaceous materials through heating in an environment of controlled oxygen. The insufficient supply of oxygen allows the material to combust, thereby, producing quality producer gas. However, in order to extract more usable producer gas, the carbonaceous material should contain moisture content in it or artificial steam should be supplied from outside. These days, coal usage has become widespread among manufacturing industries worldwide. The availability of coal reserves is much higher as compared to oil and gas reserves, which is the major reason behind the increasing use of coal gasification technology. Moreover, the increasing price of petroleum product like diesel, furnace oil, kerosene etc. has made coal-firing as primary choice, a relatively less expensive carbon-containing material. CASE Group understands coal as an excellent material to compete against other fuels more effectively. Therefore, the company offers state-of-art gasification technologies which are more environment-friendly and efficient for a number of industrial applications.

CASE coal gasifier carbonaceous material undergoes four processes

Drying & Charge Pre-Heat: The producer gas flowing upstream through the reactor dries up the newly injected coal, thus making the next stage (Pyrolysis) easier and efficient

Pyrolysis: Sometimes, called de-volatization, the condition occurs when the heated coal releases volatile resulting in up to 70% weight loss for coal. The volatiles being light in weight move upwards and the char moves downstream for the next process (Reduction).

Reduction: In this step, the char is acted upon by the Carbon dioxide and steam generated from the final process of gasification (Oxidation). Here the carbon dioxide and steam combine with char to give Carbon Monoxide and Hydrogen.

CASE introduces Pyrolysis Clean Gas Technology in India. This patented technology of our Chinese partners is a boon for the industry. Though being lower in CAPEX & OPEX, it has huge advantages over any other variants of Gasification technologies available in the world today.

THE PYROLYSIS TECHNOLOGY IS AVAILABLE IN THREE VARIANTS

Pyrolysis Hot Clean Gas Layout

Pyrolysis Clean Cold Gas Layout

Pyrolysis Very Clean Cold Gas Layout

The difference between the three variants is that in case of Pyrolysis Hot Clean Gas Station Indirect Cooler is not used and gas is available at 150 ℃ . In Case of Pyrolysis Clean Cold Gas Station Indirect Cooler is installed after the Electrostatic Precipitator bringing down the temperature of gas upto 40 ℃. In Case user requirement is of Very Clean Cold Gas Station additional ESP is installed after the Indirect Cooler to further reduce tar and dust level below 25ppm. All the above three variants gas can be pressurized to any pressure as per user requirement.

FEATURES OF ALL THREE VARIENTS

- All types of coals can be used. Bituminous coal and lignite coal can be used as the raw material for gasification.

- Coal is carbonized at low temperature in pyrolysis section and tar thus produced is of low viscosity with high fluidity.

- On account of the low viscosity and high fluidity of Tar, the chances of tar being clogged in the duct before the Purifying equipments does not exist.

- Fully automatic PLC controlled system adds to ease of Operation and lower OPEX

Zero Liquid Discharge Technology

ADVANTAGES OF PYROLYSIS CLEAN GAS STATION

- Single Gas Outlet. Gas Composition Does Not Fluctuate- Consistent Gas.

- All Purifying Equipments Are in Series- Low On CAPEX.

- Less Purifying Equipments With Simple Schematics Low On OPEX.

- Higher Purity of Gas as All Purifying Equipments Are in Series.

- Higher Gas Thermal Value.

- Usage of Gas Sensible Heat to Preheat the Incoming Coal.

- Higher Level of Pyrolysis Higher Conversion of Volatile Matter of Coal to CnHm.

- Suitable for Very Critical Heating Curves 2 ℃ Variations.

- No Refractory Used in Gasifier. Thus, Frequent Cleaning Not Required.

- 100% Recirculation of Water Condensate Zero Liquid Discharge Technology.

- Tar & Water Does Not Mix at Any Point as They Come Out from Different Discharge Points of Gasification Progress.

- Tar Fluidity Is Very Good. This Enables Tar to Be Pumped for Any Utility or Outside Sale.

- Gasifier Is in Line with Environment Protection Agencies CPCB, SPCB & MOEF & CC.

Images of Cold Coal Gasifier