A cooling tower is a heat rejection device that cools water by evaporating a small portion of it, transferring heat to the atmosphere and then recirculating the cooled water

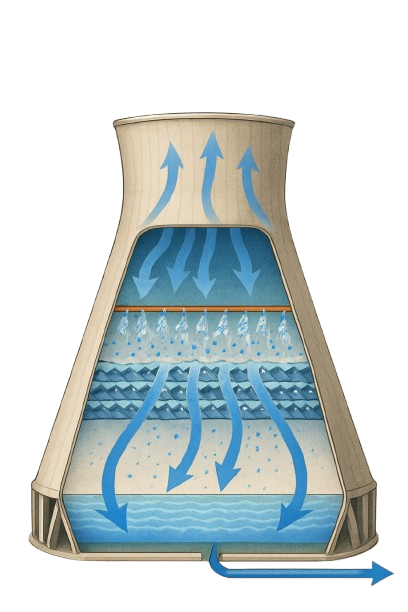

Functioning of Cooling Tower –

1 . Hot water from a heat exchanger or other source is pumped into the top of the tower and sprayed or distributed over a large surface area.

2. Air is drawn or forced through the fill, coming into contact with the water.

3 . As the water flows over the fill a portion of it evaporates, absorbing heat from the remaining water and cooling it.

4. The cooled water collects at the bottom of the tower and is then recirculated back to the system for further use.

1 . Natural Draft Cooling Tower –

The natural draft cooling tower gives the best efficiency in removing the heat from the hot water compared to the other types of the cooling tower. So, it is the best option to choose, for implementing in the industry as it has the following advantages:

- The tower does not have fans, so it is economical in price.

- It is power saving as it does not require power to run the fan.

- Easy to operate

- Maintenance cost is not high

- There is no noise produced while running.

- The smoke released from the top is environmental friendly.

- The life span period might range from 8 to 16 years.

- Operational safety

- No corrosion problems

2 . Mechanical Draft Cooling Tower –

Mechanical draft cooling towers use fans to move air through the tower either forcing it in or drawing it out, unlike natural draft towers which rely on the chimney effect. These towers utilize fans to circulate air, making them more effective and adaptable than natural draft towers.

Applications:

Mechanical draft cooling towers are widely used in various industries, including power plants, chemical plants, and air conditioning systems.

Advantages:

- The use of fans allows for better control and higher cooling rates.

- Mechanical draft towers can be installed indoors or in area with limited space, unlike large natural draft towers.

Disadvantages:

- The fans consume power, increasing operating costs compared to natural draft towers.

- The fans can generate noise which needs to be considered in the design and location of the tower.

Types of Mechanical Draft Cooling Towers –

1 . Counterflow Forced Draft Cooling Tower

In a counterflow forced draft cooling tower air is forced through the tower from the bottom by fans, moving upwards in the opposite direction of the falling water, which is distributed at the top, enhancing heat transfer efficiency. The term “forced draft” means that a fan is used to push air through the tower, rather than relying on natural draft. “Counterflow” refers to the direction of air and water flow being opposite each other. In a counterflow tower, air enters at the bottom and is forced upwards through the fill media, where it comes into contact with the falling water.

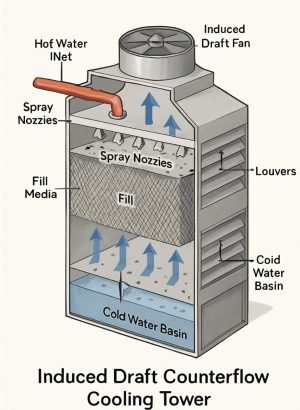

Counter-Flow Induced Draft Cooling Tower

In a counter-flow induced draft cooling tower, fans at the top of the tower draw air upwards counter to the downward flow of water, maximizing heat transfer efficiency. The term “induced draft” refers to the use of fans located at the top of the tower to draw air upwards, creating a draft.”Counter-flow” means the air flows vertically upwards, counter to the downward flow of water, which is sprayed from the top of the tower.

Working –

Water is sprayed from nozzles at the top of the tower and flows downwards through the fill media. The fans at the top draw air upwards through the fill, creating a counter-current flow of air and water. As the water flows down, it comes into contact with the air, and some of the water evaporates, which cools the remaining water. The cooled water then flows into a basin at the bottom of the tower for recirculation.

Advantages:

- The counter-flow arrangement maximizes the contact between the hot water and the cool air, resulting in efficient heat transfer.

- They typically consume less power due to their design and operation.

- Counter-flow towers are generally more compact than cross-flow towers, requiring less space.

- The vertical air discharge and low operating weight provide more design flexibility making it the preferred choice for most cooling tower applications.

Components:

- Fill Media:The packing or decking that provides a large surface area for water and air contact.

- Water Distribution System:Nozzles or spray systems that distribute the hot water evenly over the fill.

- Fans:Axial fans located at the top of the tower that draw air upwards.

- Drift Eliminators:Devices that prevent water droplets from being carried out of the tower with the discharged air.

- Basin: A reservoir at the bottom of the tower that collects the cooled water.

Cross-Flow Induced Draft Cooling Tower

In a cross-flow induced draft cooling tower, water flows vertically through the fill while air flows horizontally across it, and fans at the top exhaust the air, making it a compact and energy-efficient heat exchange system.

Working :

Water enters the top of the tower and is distributed through spray nozzles, flowing vertically downwards through the fill (a heat exchanger). Air enters the sides of the tower and flows horizontally across the water, in a direction perpendicular to the water flow. As the water drips through the fill, some of it evaporates, which cools the remaining water. Fans at the top of the tower draw the air, which is now cooler and more humid, and exhaust it out of the tower.

Advantages of Cross-Flow Induced Draft Towers:

- They have a more compact design compared to other types of cooling towers, making them suitable for installations with limited space.

- They are easy to maintain because the air does not pass through the distribution system, allowing for the use of gravity flow hot water distribution basins mounted at the top of the unit above the fill.

- They are suitable for various industries and can be easily adjusted and modified according to industry needs.

- They are environmentally friendly because they use less water and energy.