Understanding Coal Gasification: Process, Benefits, and Global Applications

Coal gasification is a modern energy conversion technology that transforms coal into a cleaner, more versatile form of fuel known as syngas or synthetic gas. This process offers a way to utilize coal resources with improved efficiency and reduced environmental impact.

In this blog, we explore what coal gasification is, how it works, its benefits, applications, and global relevance in today’s energy and industrial landscape

What is Coal Gasification?

Coal gasification is a thermo-chemical process in which coal is converted into gas by reacting it with oxygen and steam at high temperatures under controlled conditions. Rather than burning the coal directly, the process partially oxidizes it to produce a combustible gas mixture called syngas.

Syngas typically contains:

- Carbon monoxide (CO)

- Hydrogen (H₂)

- Methane (CH₄)

- Carbon dioxide (CO₂)

- Water vapor (H₂O)

- Trace gases (e.g., sulfur compounds)

How Does the Process Work?

The gasification process generally follows these stages:

- Drying: Moisture is removed from the coal.

- Pyrolysis: Coal is heated in the absence of oxygen to release volatile gases.

- Oxidation: A controlled amount of oxygen or air is added to partially combust the coal, generating heat.

- Reduction: Steam reacts with hot carbon to form syngas through water-gas reactions.

Depending on the type of gasifier used (fixed bed, fluidized bed, or entrained flow), the design and efficiency may vary.

Types of Coal Gasifiers

There are several types of gasifiers used in industrial and power applications:

- Fixed Bed Gasifier: Simple design, used in smaller applications.

- Fluidized Bed Gasifier: Efficient for low-grade coal; allows uniform temperature distribution.

- Entrained Flow Gasifier: Operates at higher temperatures; suitable for large-scale production and cleaner output.

- Underground Coal Gasification (UCG): Converts coal to gas while it is still underground—suitable for deep or unmineable coal seams.

Types of Fixed bed Gasifiers

- Based on slagging (hot ash melting) process.

- Suitable for high-demand industries requiring high calorific value gas.

- Gas output is hot only, suitable for direct use in high-temperature processes.

- Fully PLC-controlled with advanced features for higher efficiency.

- We works with all types of coal including high-ash varieties

- Gas outlet temperature is high, so tar is in a gaseous state, resulting in high calorific value.

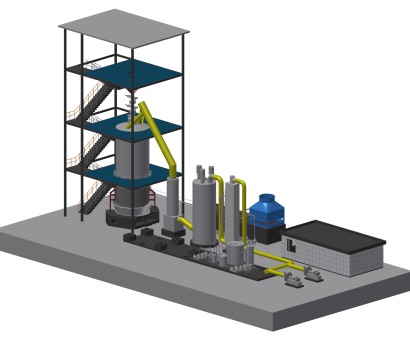

Hot Coal Gasifier

Hot Coal Gasifier Station

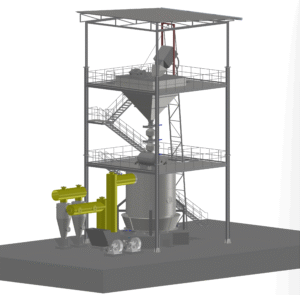

- Based on dry ash removal process

- Gas output is cleaned and cooled for industrial usage.

- Operates at lower temperatures to ensure tar recovery and reduce thermal stress.

- Tar is recovered as a by-product.

- Simple design with less complex slag handling

- Ideal for small to medium industries needing moderate clean gas output.

- Controlled through PLC automation for safe and reliable operation

- Works well with all types of coal

- Focuses on clean energy with efficient gas generation and lower emission

- Used in various industrial heating applications.

- Ensures clean fuel generation with higher thermal efficiency.

- Burner-level automation possible.

Advantages of Coal Gasification

- Fuel Flexibility: Can utilize low-grade coal and waste coal.

- Cleaner Combustion: Lower SOx, NOx, and particulate emissions than direct coal combustion.

- Energy Efficiency: Higher thermal efficiency compared to traditional methods.

- Feedstock for Chemicals: Syngas can be converted into ammonia, methanol, or synthetic fuels.

- Hydrogen Production: A source of hydrogen for fuel cells or green energy systems (with carbon capture).

Global Applications and Relevance

Coal gasification is widely used in:

- Power Generation: Integrated Gasification Combined Cycle (IGCC) plants convert syngas to electricity more cleanly.

- Industrial Heating: Used in steel, ceramics, cement, and glass industries as a substitute for oil and natural gas.

- Chemical Industry: Produces methanol, urea, and synthetic fuels.

- Hydrogen Economy: A bridge to hydrogen production with potential for carbon capture and storage (CCS).

Countries actively using coal gasification:

- China: World leader in coal gasification projects, especially for chemicals.

- South Africa: Long history of synthetic fuel production from coal (e.g., Sasol).

- India: Growing interest in coal gasifiers for energy and industrial applications.

- United States: Focused on research and IGCC development.

Environmental Considerations

While cleaner than direct coal combustion, coal gasification still emits CO₂. However, the syngas can be treated more easily before combustion, making carbon capture and storage (CCS) more effective.

Challenges include:

- Water consumption

- High initial costs

- Complex technology requiring skilled operation

With proper safeguards, gasification can serve as a transitional technology toward lower-carbon energy systems.

Future of Coal Gasification

As countries look to diversify energy sources and reduce carbon footprints, coal gasification offers:

- A cleaner use of coal reserves

- A bridge to the hydrogen economy

- An opportunity for waste-to-energy integration

- Carbon capture-ready systems for emission reductions

The future of coal gasification depends on technological advancements, environmental policies, and global energy transitions

Conclusion

Coal gasification represents a flexible and cleaner way to utilize coal for energy and industrial processes. With proper infrastructure and policy support, it can play a significant role in improving energy security, reducing emissions, and producing valuable chemical feedstocks.

As the global energy landscape evolves, coal gasification stands at the intersection of industrial innovation and environmental responsibility.

Recent Blogs

-

How Gasification Technology Can Make India Self-Reliant in Industrial Energy Demands.How Gasification Technology Can Make India Self-Reliant in Industrial Energy Demands.

-

Why CASE Group is a Leading Clean Coal Gasifier Manufacturer in IndiaWhy CASE Group is a Leading Clean Coal Gasifier Manufacturer in India