Coal continues to play a

major role in industrial

energy supply, but traditional

usage poses challenges

such as harmful emissions

and health risks. To address

these issues, coal

gasification has emerged as

a cleaner and more efficient

alternative. The process

converts coal into synthesis

gas (syngas) at high

temperatures with limited

oxygen, producing a

versatile fuel with higher

calorific value and reduced

environmental impact.

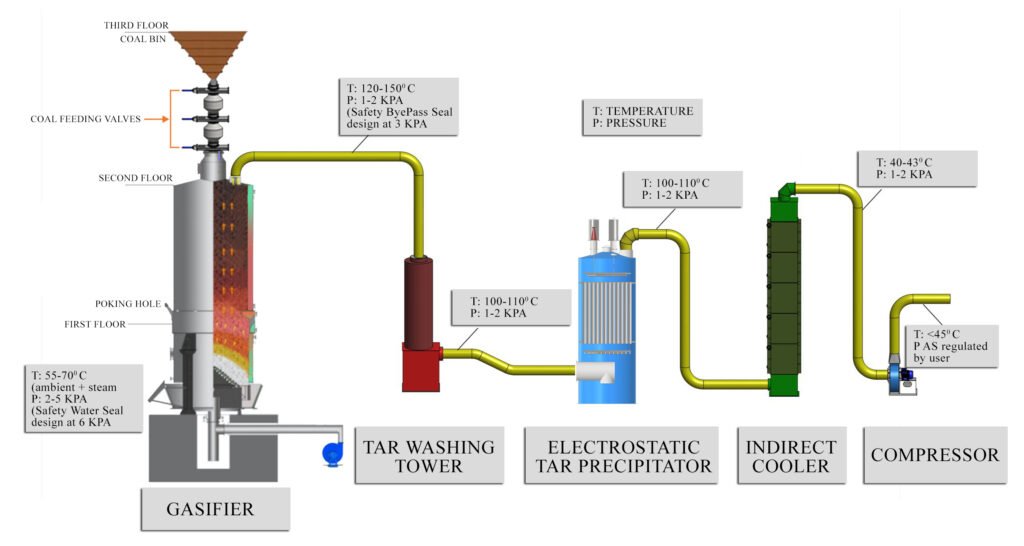

CASE Group, a technology

provider in this space, has

developed clean cold

gasifiers that operate

through a series of

controlled stages. Coal is

first fed into the hearth via

conveyor belts, undergoing

drying, pyrolysis, reduction,

and oxidation. These

sequential reactions

transform the coal into

producer gas.

The gas then passes

through downstream

cleaning equipment. In the

Tar Washing Tower (TWT),

tar particles are removed

through a seeding process,

reducing the load on

subsequent systems. The

Electrostatic Tar Precipitator

(ESP) applies high-voltage

corona discharge to separate

heavier tar residues, while

the Indirect Cooler (IDC), a

fin-tube heat exchanger,

lowers the gas temperature

to below 45°C. CASE Group

also ensures Zero Liquid

Discharge (ZLD) by treating.

and reusing phenolic

wastewater generated during

the process.

The resulting clean

syngas can be compressed

and supplied for use across

industries including

steelmaking, rolling mills,

pellets, ceramics, and more.

Even the ash residue from

gasifiers finds utility in brick

manufacturing, contributing

to circular resource use.

With India aiming to reduce

fuel imports and transition

toward greener technologies,

gasification offers a viable

pathway for sustainable

energy use. By providing

cleaner alternatives while

ensuring efficiency, the

technology is gaining wider

acceptance across energyintensive sectors.